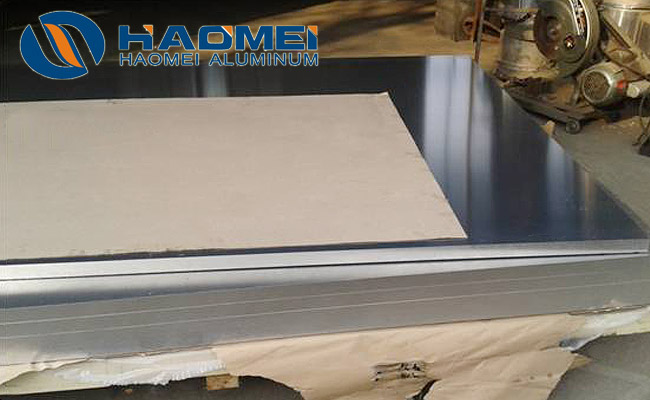

High quality 4 by 8 aluminum sheets supplied by Haomei has no cracks, corrosion spots and traces of nitrate on the surface. The surface shall be free of scratches, bumps, cracks, blisters, stains, deformation, sand holes, traces, corrosion and other damages. Aluminum is a very important metal, because of its excellent performance, aluminum plays an important role in modern industry. In order to facilitate transportation, aluminum is generally processed into aluminum sheets with different thickness, which is convenient for transportation to all parts of the world, the common used specification is 4 by 8 aluminum sheet.

Because of the huge difference in transportation and storage environment, aluminum sheet often suffers from scratch, deformation, oxidation and other losses, so it is necessary to properly package aluminum sheet. When it comes to 4×8 aluminum sheet, the first thing we should think about is the cold rolling process. The rolling process below the recrystallization temperature of metals and alloys is called cold rolling. In cold rolling, although the deformation heat and friction heat of the metal can also make the temperature of the rolled piece high and have a certain recovery effect, the main role in the cold rolling process is cold work hardening (work hardening).

Compared with hot rolling, the main feature of cold rolling is that the thin strip can be obtained. Generally, the thickness of hot-rolled 4 by 8 aluminum sheets is 6-8mm. The minimum thickness is 2.5mm-3.0mm. Generally, the cold rolling mill can roll to 0.5-4.5mm. The more advanced cold rolling mill can roll out extremely thin or thick foil with a thickness of 0.1mm-0.2mm.

Contact Us

- 1103, No.14 Waihuan Road, CBD,Zhengzhou, China

- +86-0371-65621391

- nydia@aluminumhm.com

- Contact Form